Rotational Molding Request Quote

Rotational Molding Categories

Granger Industries Inc. Related Links

Since 1994 Granger Industries has provided industry leading solutions for a range of industries spanning from Aerospace, Defense, OEM Manufacturing, Agri-Products, Safety, Material Handling, Recycling and so much more. Granger actively pursures "Solutions beyond Expectations" for all customers, large and small.

Rotational Molding Tooling or Molds

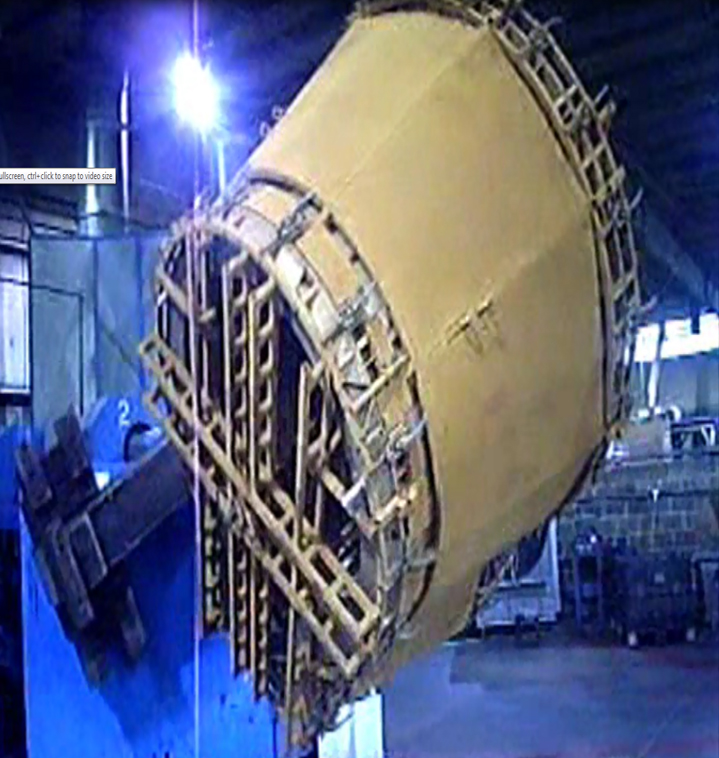

Fabrication of Rotomolding Tooling

Molds for rotomolding are typically manufactured from aluminum, steel, stainless steel or even brass. Rotomolding Tooling is typically produced by either means of fabrication, casting or even machining Some Rotomolding leaders have developed the ability to build hybrid tooling which allows for various complex features and in some scenarios faster turn around times. Rotomolding tools are necessary to produce actual rotationally molded products. You can prototype Rotationally molded products via various alternative means and methods, but to prototype an actual rotomolded product, you will have to be build the necessary tooling. The upside to this is that in comparison to the most common plastic manufacturing processes, Rotational Molding tooling is typically a fraction of injection or blow molding molds. Sometimes to the point that Rotational Molding can be an attractive option to do product testing in a market prior to major mass production.

|

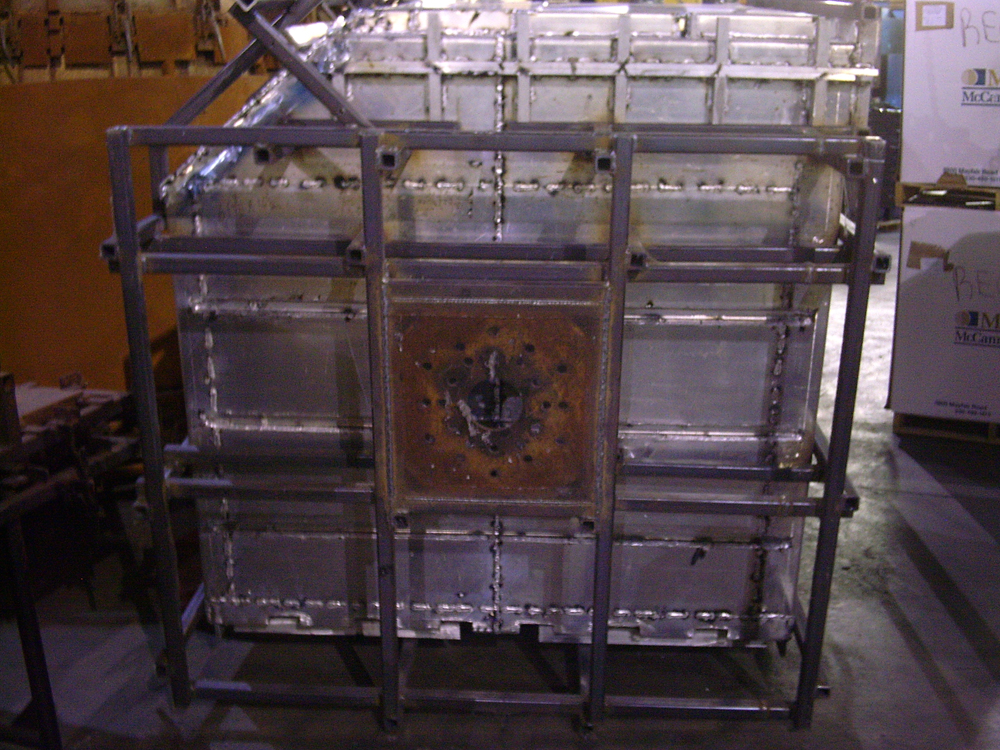

Rotomolded Tooling, is one of the integral initial capital investments that is required to produce a Rotationally Molded Product. Today's leading Custom Rotational Molding houses are typically forced to have in house tooling centers and repair shops to keep their customers production going, requiring running tools and also to consistently grow new customers with new tooling. Unfortunately for many Rotational Molding Companies, they do not not offer in house rotational mold tooling maintenance, nor do they build tooling in house. Therefore when your tooling cracks, frame work breaks or the parting line gets damaged, not only are you out of production, you could be out of production for months! As they will have to send your tooling out to another shop to fix. Costing you loss of production, loss of sales and ultimately loss of profits! Don't risk your business or your customer relationships to such! The prices for Rotomolding tools are generally competitive amongst most quality molders, yet some still risk their business on poor tooling with numerous issues! Rotomolding tooling is generally no different than most other things in life, you get what you pay for!

|

|

|

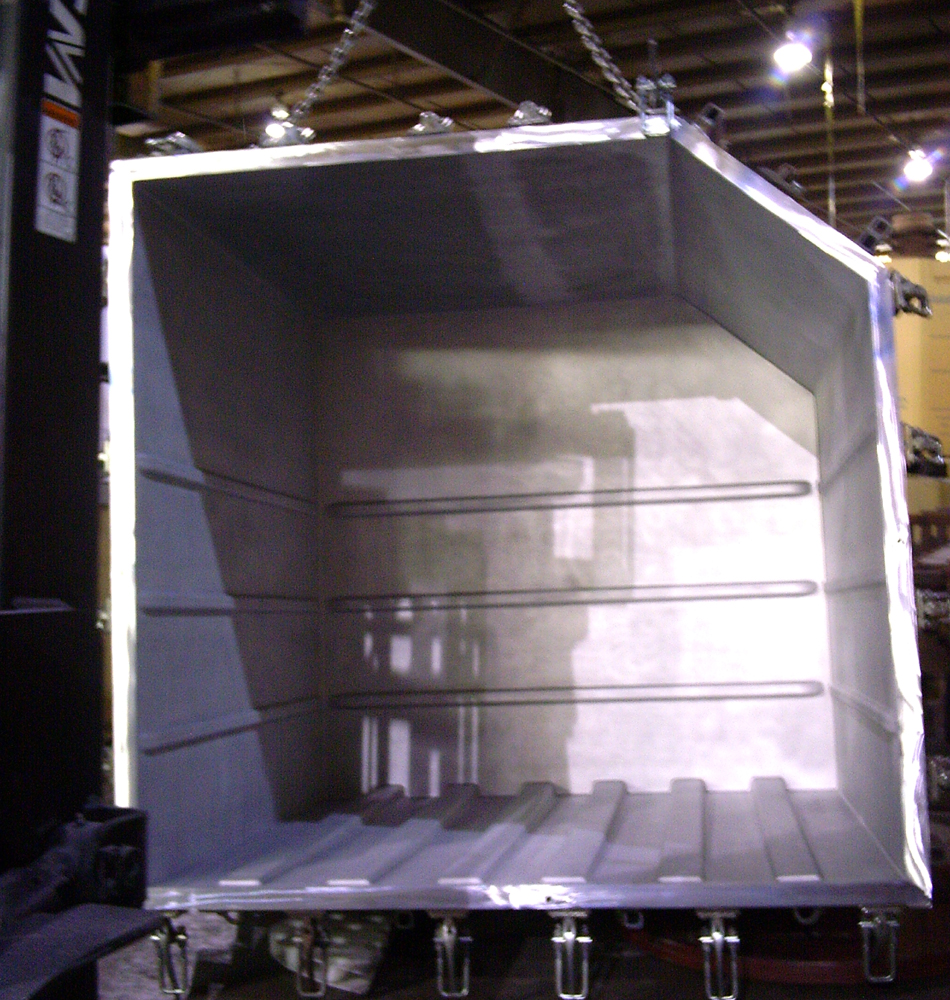

The Granger ISS Tornado Shelter mold is a great example of a high quality mold that required lots of innovation and design to accomplish its goals. A number of trade secrets help manufacture the Granger ISS, but the mold is consistently in production and has undergone a number of moldifications even. It's the heavy duty framework and the heavy duty clamps that make one of the biggest differences in rotational molds being manufactured and parts being produced by Granger Plastics.

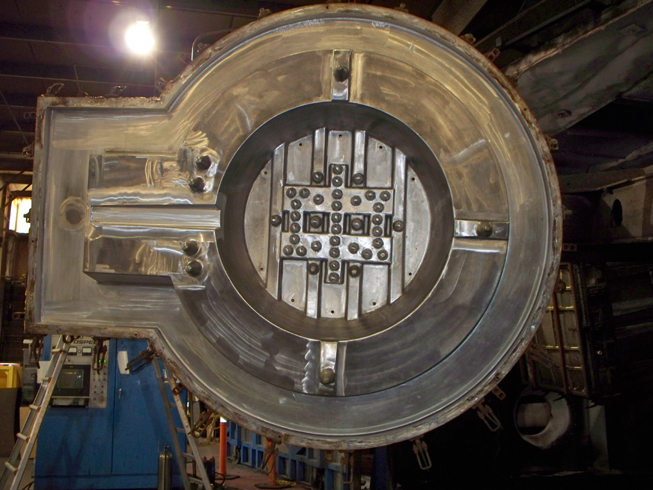

The picture above displays the inner plug of the Granger ISS Tornado Shelter mold being pulled. This is probaby the most integral part of the monsterous 3 piece tooling. Also notice the high quality mirror polish finish on the plug of the Tornado Shelter tooling. This allows for a very nice high polished inside surface on the finished product. The tooling for the Granger ISS is probably one of the most intricately designed Rotational Molds in the industry, also while potentially being one of the most expensive. Granger Plastics has performed some pretty astonishing feats inside of its mold shop and metals fabrications departments .

|

|

|

Good quality Rotational Molding tools or molds are built with heavy duty frame work, this helps keep the tooling in good shape and allows the tooling to maintain significantly better than tooling with thin gauge tubing and light weight clamps. Heavy Duty clamps will go miles further in the long run and keep your tooling running and in better shape overall

|

|

If your tooling is fabricated by Granger Plastics Mold Shop, another advantage is that as long as your tooling is in production at Granger Plastics or a Granger Industries Facility, Granger Plastics will maintain your tooling free of charge. While most other most mold shops will nickel and dime you to death over your tooling expenses such as clamp replacements, sandblasting, mounting plates, small weld repairs, some molders will even charge to store your tooling! Granger Plastics wants your tools in production, producing quality products for you to satisfy your customers, thus making it a prosperous and beneficial relationship for all of us.

Rotational Molding Mold Shop Video

COMING SOON!